The functioning of horizontal directional drilling

The horizontal directional drilling method represents an outstanding example of technical skill and precision in the construction industry. With exceptional expertise and remarkable accuracy, it penetrates even the most challenging substrates, following a plan that guarantees results to the millimeter. The individual steps of this method impressively demonstrate how determination and innovative technology go hand in hand:

Before the actual drilling begins, it is crucial to conduct comprehensive planning. This means thoroughly examining the substrate and determining the best route for the pipelines. We ensure that all necessary data and factors are taken into account to make the implementation as efficient and safe as possible.

The actual drilling process begins with the pilot drilling. A specially designed drill head slowly works its way through the ground, clearing the path for the later pipelines. This initial drilling precisely follows the previously determined path to ensure the accuracy of the entire process.

After the pilot drilling, we enlarge the borehole to the required diameter. For this, we use reamers that gradually break up the ground, making the path smoother for the pipes.

Now the final step of the drilling process begins. The prepared pipelines are carefully inserted into the enlarged borehole. With the help of our precise machine guidance, we ensure that the pipes land exactly in the planned position. This guarantees that the infrastructure is ready for its intended use without complications.

Each of these steps is executed with the utmost professionalism, always aiming for maximum efficiency and customer satisfaction. Our goal is your satisfaction – we won’t rest until your vision is anchored in the ground with absolute precision.

The Components of a Horizontal Directional Drilling Rig

A horizontal directional drilling rig consists of several key components essential for the successful execution of the drilling process. Below is a list of the main components:

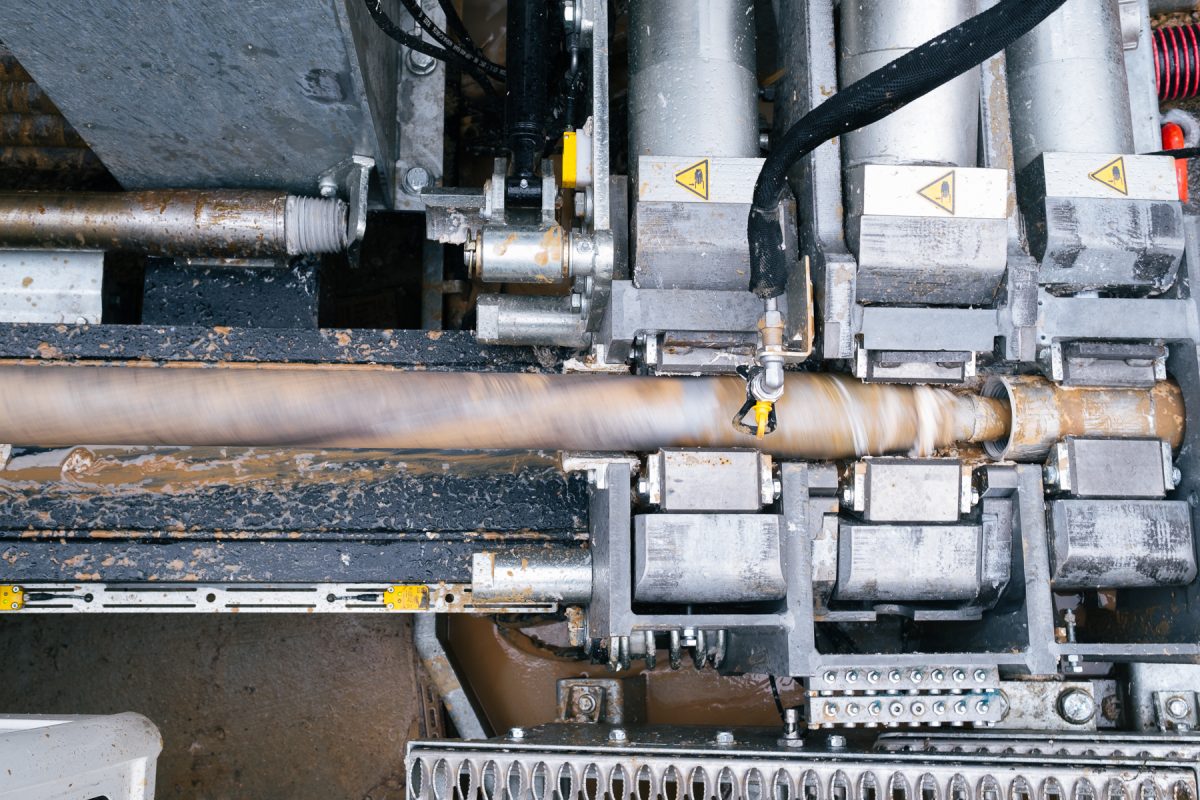

- Drilling Rig: The heart of the entire operation, equipped with high power to precisely control the drill head.

- Bentonite Mixing Unit: A crucial facility that prepares the bentonite slurry. This slurry is used to stabilize the borehole and transport drill cuttings to the surface.

- Recycling Unit: This unit separates the bentonite slurry from the drill cuttings so that it can be reused in the drilling process, providing both economic and environmental benefits.

- Control Unit: Using advanced electronics, this unit monitors and controls the drilling process to ensure the highest precision.

- Supply Lines: These lines transport the drilling fluid to and from the drill head and are essential for continuous operation.

- Pumping Systems: These systems build the necessary pressure in the drilling fluid circulation system and assist in the removal of dissolved materials.

- Pipe Handling System: A device for transporting and precisely placing the pipes to be pulled into the borehole.

Each of these components plays a critical role in the functionality and efficiency of a horizontal directional drilling rig. The integration of bentonite mixing units and recycling units exemplifies the intelligent and sustainable aspects of modern construction technology.

Advantages of the Horizontal Directional Drilling Method

The advantages of the horizontal directional drilling method are compelling and multifaceted. This method symbolizes a new era in construction technology, where efficiency and environmental protection go hand in hand. With minimal surface disruption, this technique allows for significantly faster project completion while simultaneously creating high-quality infrastructure. It results in less traffic disruption, lower emissions, and reduced noise-related disturbances. From a business perspective, adopting this technology represents a clear competitive advantage – it demonstrates foresight, innovation, and a sincere commitment to ecological standards.

Environmental Protection

Less soil intrusion and a reduced carbon footprint compared to traditional construction methods.

Cost Efficiency

Efficient and rapid project execution without extensive earthworks, leading to long-term savings.

Time Savings

Rapid project implementation for pipeline installation makes it equally attractive for clients and end customers.

Safety

Increased safety for construction workers and pedestrians through the method: deep excavations and associated risks are eliminated.

Applications for the HDD Drilling Method

Modern infrastructure development faces numerous challenges, especially in densely populated, historical, or urban areas. The horizontal directional drilling (HDD) method has proven to be a revolutionary technique that supports a wide range of applications and enhances efficiency in the installation of pipelines and cables, while minimizing surface disruption. From water supply systems to telecommunications networks and urban renewal projects, this method offers a future-proof solution for the ever-evolving demands of urban and rural infrastructure.

Water Supply and Disposal: Laying fresh water pipes, sewage pipes, and stormwater drains, especially in densely populated or historical areas where traditional excavation methods would be impractical.

Biogas Pipelines: Installing high and low-pressure gas pipelines under rivers, roads, and built-up areas without disturbing the surface.

Telecommunication: Installing fiber optic, coaxial, and telephone cables, particularly in urban areas, to accelerate network expansion and reduce overall construction efforts.

Heating and Cooling: Installing geothermal heating and cooling systems, where the horizontal directional drilling method facilitates the installation of vertical or horizontal loops.

Road and Railway Crossings: Instead of opening surface traffic routes, the horizontal directional drilling method enables the installation of pipelines and cables beneath these obstacles.

River and Canal Crossings: Ideal for laying pipelines under waterways without impacting the ecosystem or navigation.

Urban Renewal Projects: In older cities where the underground is already crowded with existing utilities, the horizontal directional drilling method offers a less invasive way to add new infrastructure or replace old systems.